Mylon Metallics was incorporated as an engineering company par excellence for manufacture of engineering products that will find applications in

Textile mills - Machines, spares and services .

Transport sector - Refrigerated insulated trucks for perishables

Original Equipment - Manufacture supplies

Mylon is promoted by professionals with over 35 years of experience in various fields of design, manufacture, marketing and technical services. The reputation gained with over 800 customers in India and abroad is the biggest asset for the company. Mylon is built with a modern PEB structure of 12000 sq ft with EOT crane and other latest gadgets and CAD software to meet the manufacturing requirements. Further CNC machines for sheet metal and metal cutting are shared with other dedicated suppliers in the manufacturing hub of Coimbatore.

Mylon with the facility to manufacture and experience in engineering has ventured into the manufacture of Insulated Containers for perishables.

GRP Insulated containers.

Alumnium Insulated containers

Steel Insulated containers

Dry containers

Ice creams .

Fish & Poultry.

Cakes & Pastry

Vegetables

Milk and milk products

Have an association with COOLTECH Containers for marketing and technical support

Association with reputed Air conditioning & Refrigeration companies like Carrier Thermo King, Tessol to offer complete package .

Experience in working with all reputed truck manufacturers like Bharat Benz, Ashok Leyland, TATA, Isuzu, Eicher. .

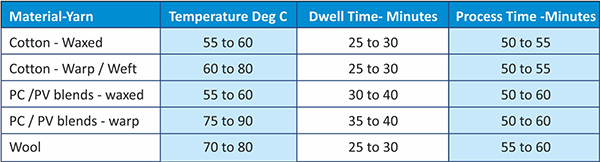

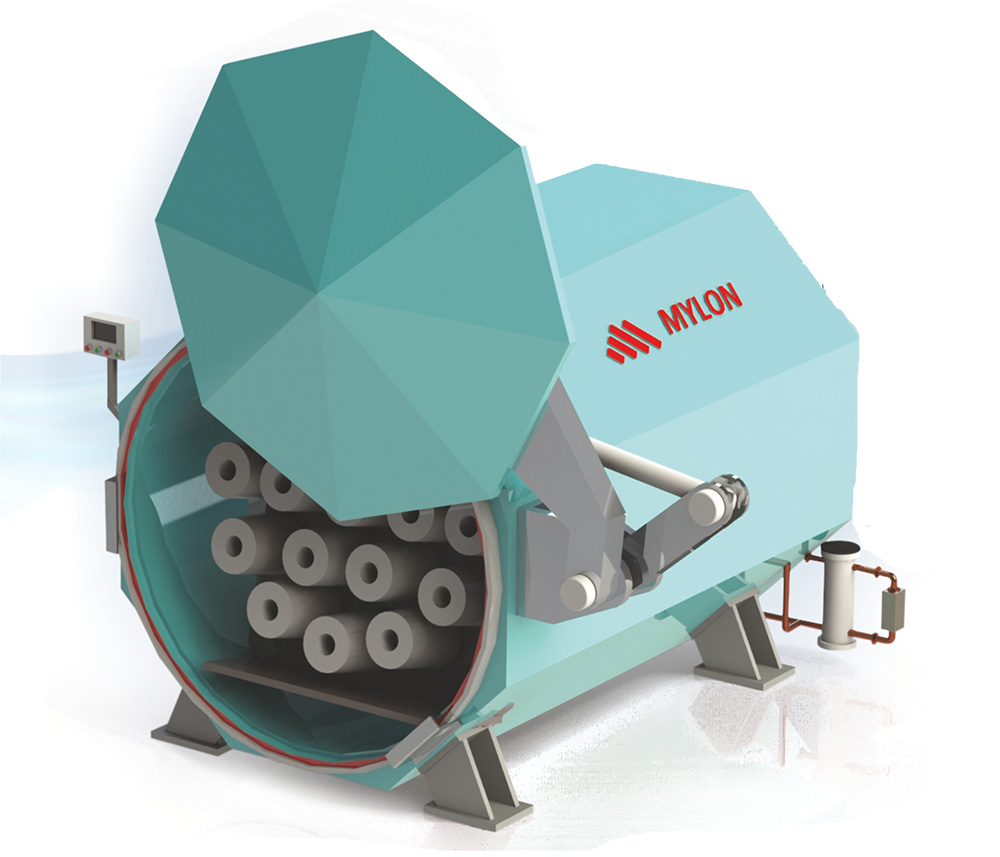

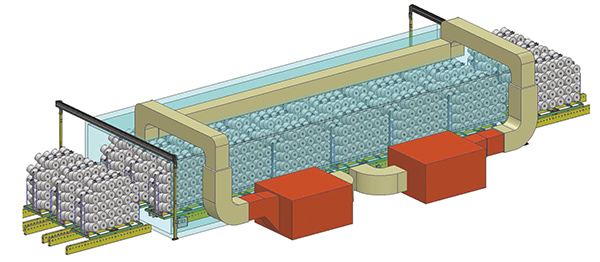

Yarn loses the moisture during spinning process from blow room to winding. To regain the lost moisture various methods were followed. The process of yarn conditioning has been perfected over the years with vacuum steaming of yarn.

Yarn elongation and strength.

Better performance at warping, weaving and knitting

Reduced snarling

Reduced fly liberation

Optimum moisture in yarn

Cotton .

Cotton blends with Rayon/Viscose.

Cotton blends with Polyester

Worsted /Woollen yarn

Conditioning of yarn in atmospheric conditions take several hours for moisture to penetrate the inner layers of cone / cheese

Generation of steam under vacuum is an established process of conditioning that offer the advantages as:

Helps in generation of steam at lower temperature.

Better penetration of steam across several layers of yarn homogeneously

Shortened conditioning time

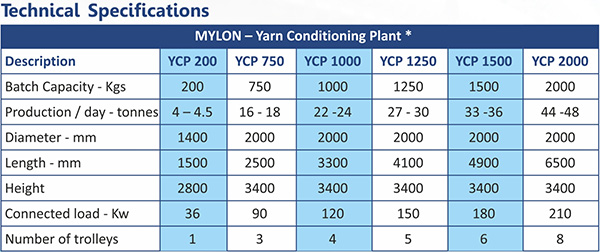

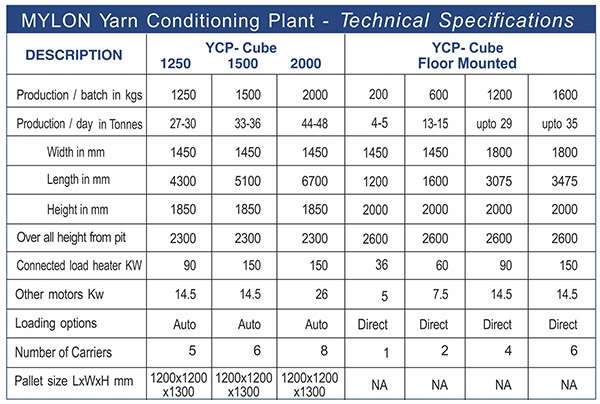

Specifications are subject to change.

Batch capacity will depend on cone diameter and weight of cones

Production capacity will depend on process parameters

Heating options : Electrical, Steam, Dual , Gas

Material loading : Trolleys with automatic loading platform

Specifications are subject to change.

Batch capacity will depend on cone diameter and weight of cones

Production capacity will depend on process parameters

Heating options : Electrical, Steam, Dual , Gas

Material loading : Trolleys with automatic loading platform

Yarn Conditioning A typical conditioning improves the moisture in yarn by 1.5 to 1.8 % depending on the yarn / fiber properties and conditioning parameters. Certain application may require higher increase in moisture. Pre / post conditioning of the yarn increases the moisture by 0.2 to 0.5 % depending on the duration of the process, yarn /fiber properties.

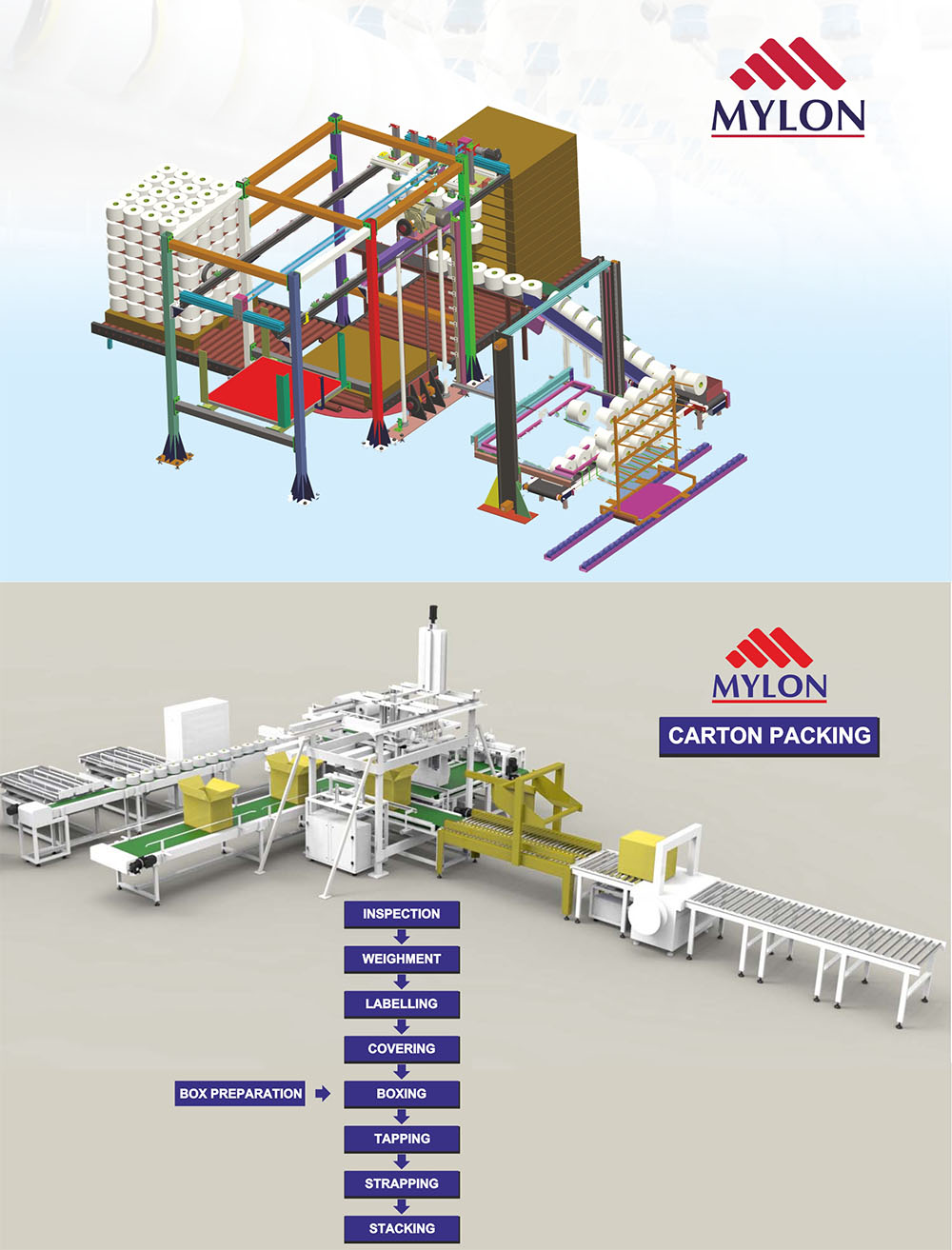

Yarn Packing The next sequential process of any conditioning process is packing. MYLON offers different packing solutions to meet the requirements of spinning mills.

Stretch Wrapping Machine - for packing of cones in a pallet with stretch film.

Carton Packing Machine - for packing of cones in cartons. Individual cones are inspected, wrapped in poly sheets and stacked in Carton boxes. Automated case erectors, taping machines, strapping machines and labelling can be integrated to offer a complete packing line.

Bag Packing Machine - for packing of cones in bags. Individual cones are inspected, wrapped in poly sheets and stacked in HDPE bags.

Yarn Conditioning.

Spares.

Trolleys.

Service.

Plant Yarn Conditioning Machines supplied by several reputed suppliers in the past 20+ years are in operation in most of the spinning mills. These machines need spares and services from experts with vast experience in conditioning. Mylon offers all the essential spares, PLC , Electrical and Mechanical upgrade kits for improving the performance of conditioning machines at an economical cost.

Mylon Metallics Pvt Ltd

Factory: SF 38/2, Arasur, Near LMW Foundry Division,Coimbatore 641407

Office : 46 , Bharathi Nagar Peelamedu, Coimbatore-641004.

+91-9894756798 , +91-9077033798, +91-9047022798